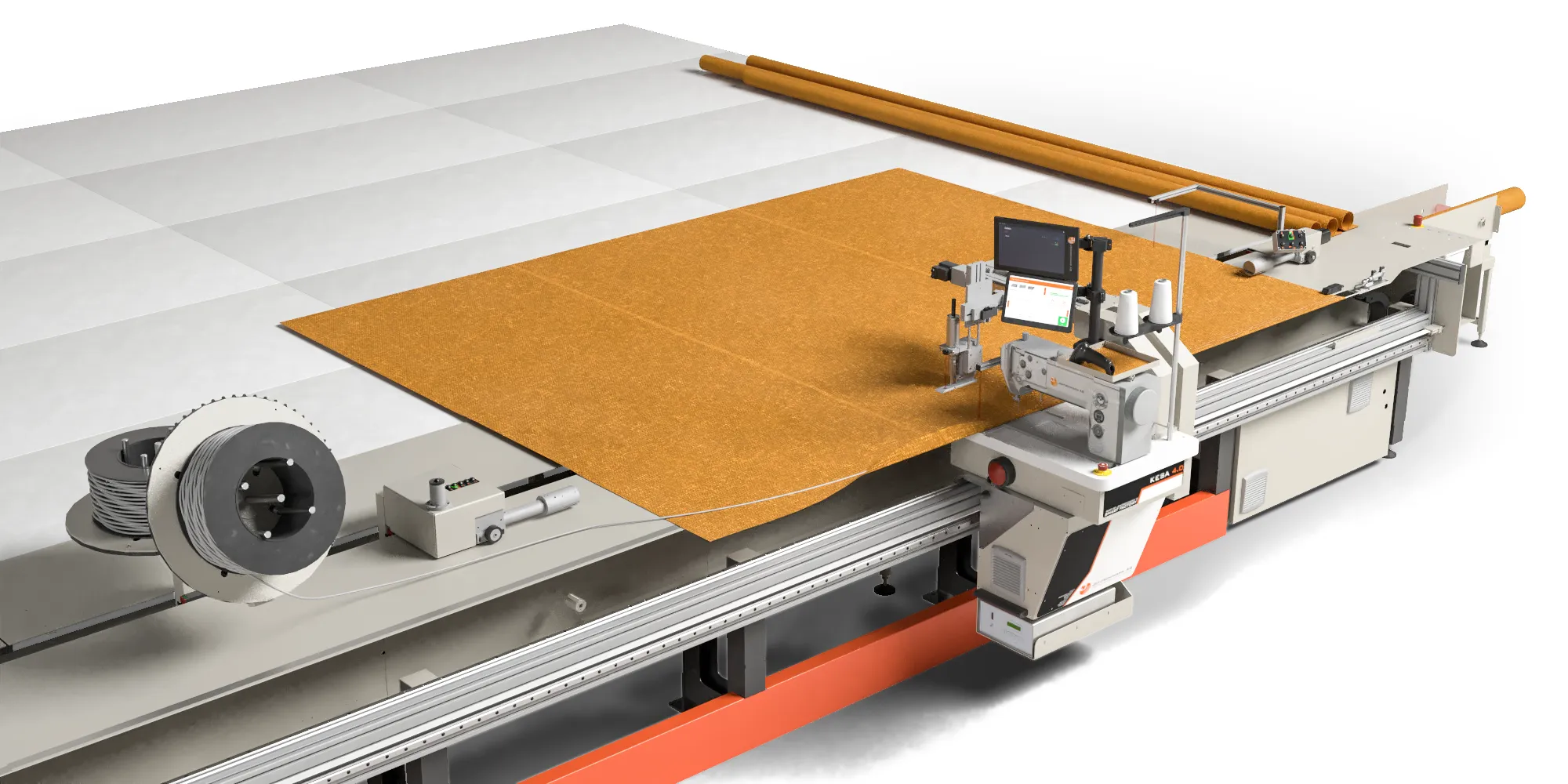

KESA 4.0

HIGH-PERFORMANCE SEWING UNIT

The completely redesigned Kesa 4.0 is characterised by numerous new smart functions that make the processing of technical textiles, such as awnings or banners, easier and more efficient. It is mainly used for typical edge processing, such as attaching a piped hem or hemstitch, applying Velcro and fleece tapes, flat piping or various other piping.

NOW EVEN

Smarter

PROCESS DATA

IN

REAL TIME

NOW EVEN

Smarter

PROCESS DATA

IN

REAL TIME

4.0 FUNCTIONS

The new high-performance control generation allows a large amount of process data to be recorded in real time and fed back into the Jentschmann MES system NODE.

MODERN HMI

The machine now features a 10" touch display with 1920 x 1200 resolution in a highly modern UI design.

ADJUSTABLE DISPLAY

The position and angle of the touch display can be adjusted to the operator preference.

Smart features that make work more efficient.

REMAINING THREAD MONITOR

Bobbin capacity is monitored and displayed as remaining sewing length in meters. This makes it easy to determine if the next seam can be completed or bobbin change is required first.

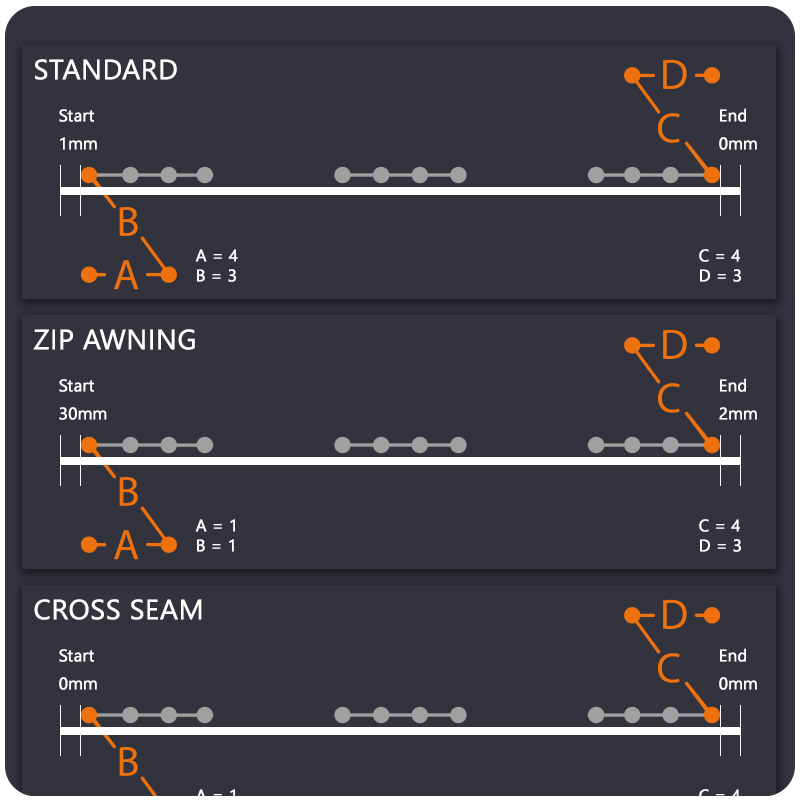

SEAM PROGRAMS

Seam sequences for various operations are easy to make, save, and recall directly on the machine. Start and end positions, back tacks, and intermediate stops / tacks can be adjusted as required.

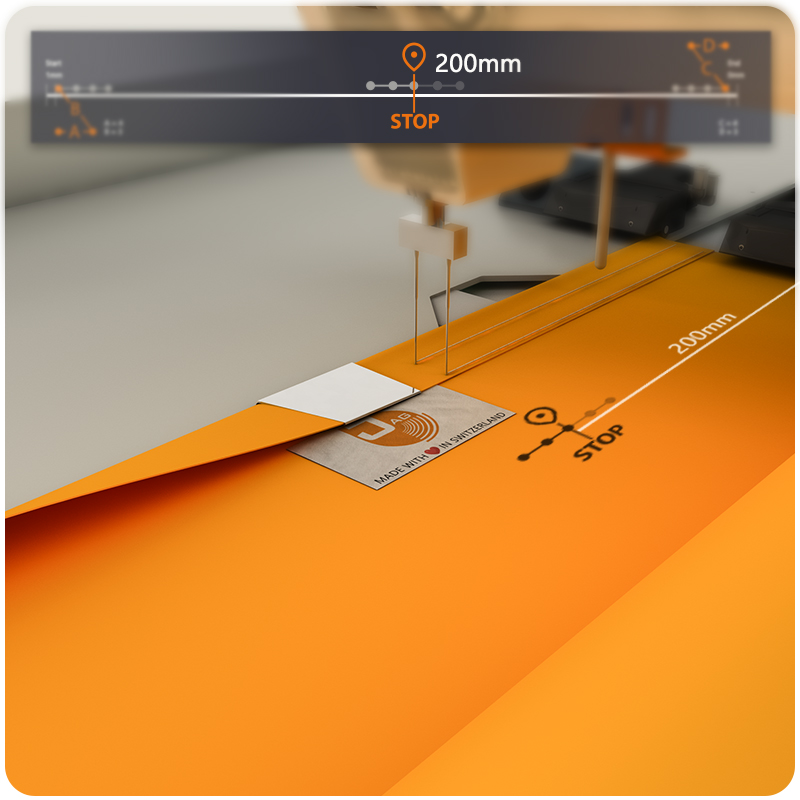

LABEL POSITION

If labels are sewn into a side hem, the machine can stop at the defined position and resume sewing after operator inserts the label.

OPERATIONS

TEXTILE SUN SHADING

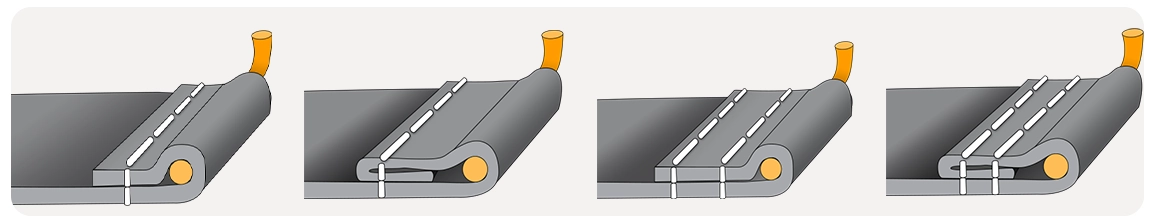

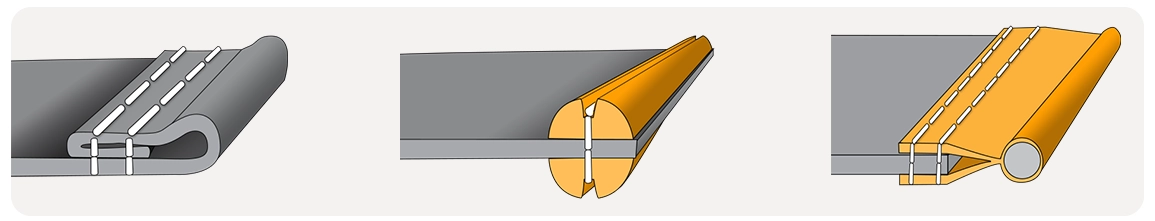

Standard edge finishes for the production of awnings:

hem with 1-needle / double hem with 1-needle / hem with 2-needle / double hem with 2-needle

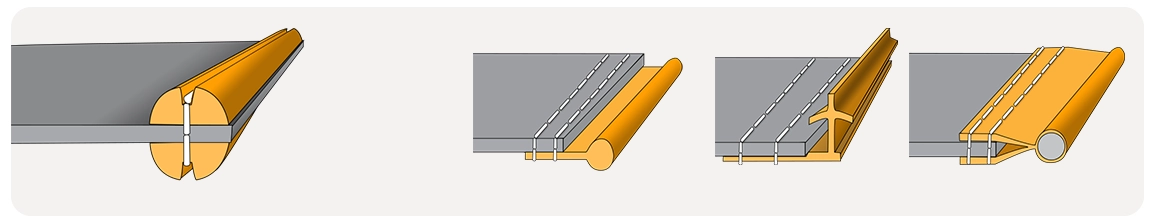

Further processing is also possible using special guiding devices, e.g:

NonVi Twin S / flag piping with 1 flag / plug-in piping / flag piping with 2 flags

DIGITAL PRINTING

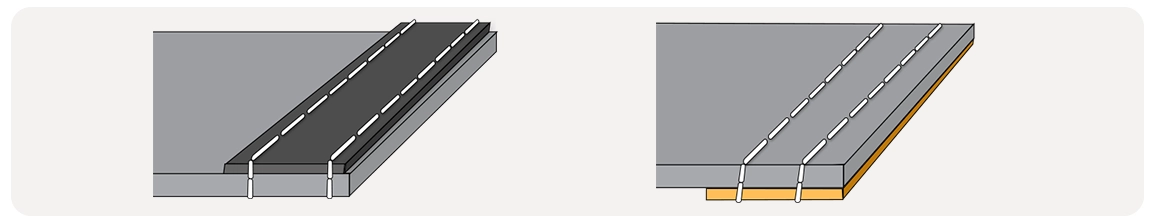

Typical edge finishes for the production of banners and flags:

simple hem / NonVi Twin S / Flag piping with 2 flags

other typical edge finishes for the production of banners and flags:

Velcro tape (hook and loop tape) / flat piping

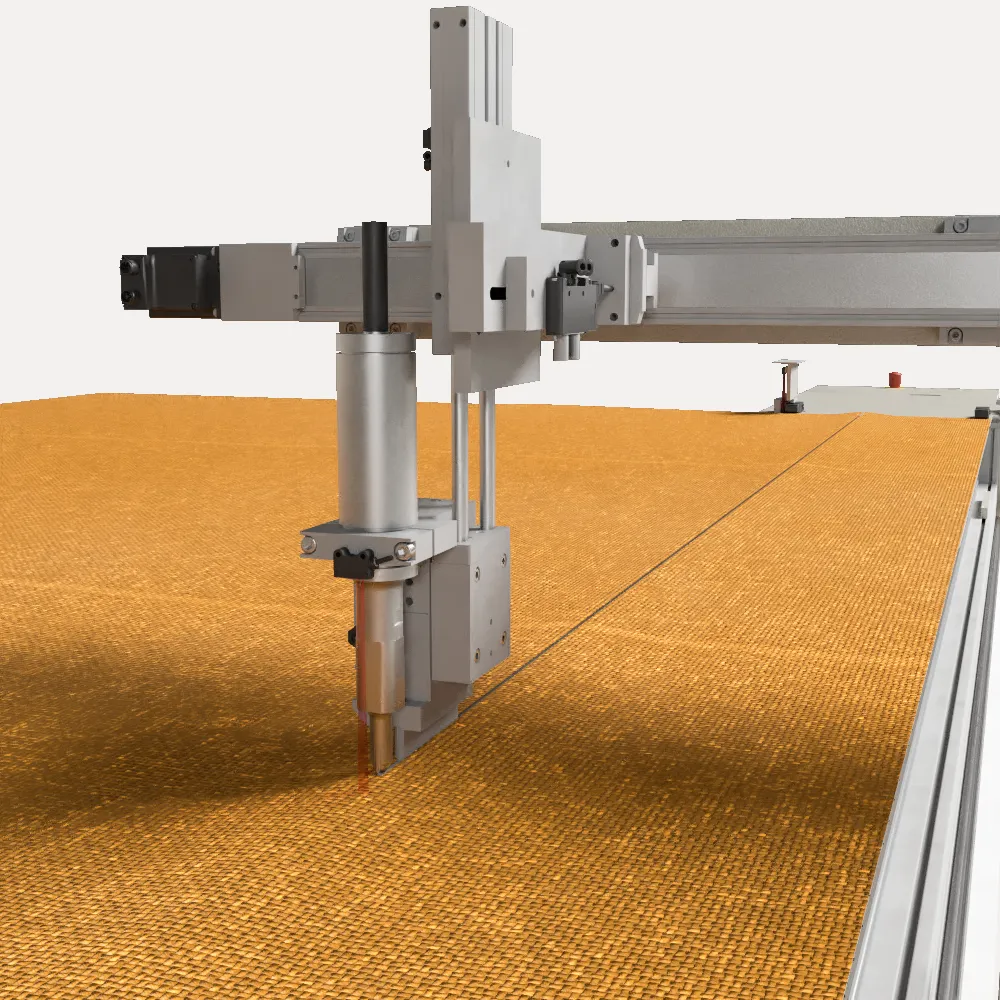

THE LATEST INNOVATION

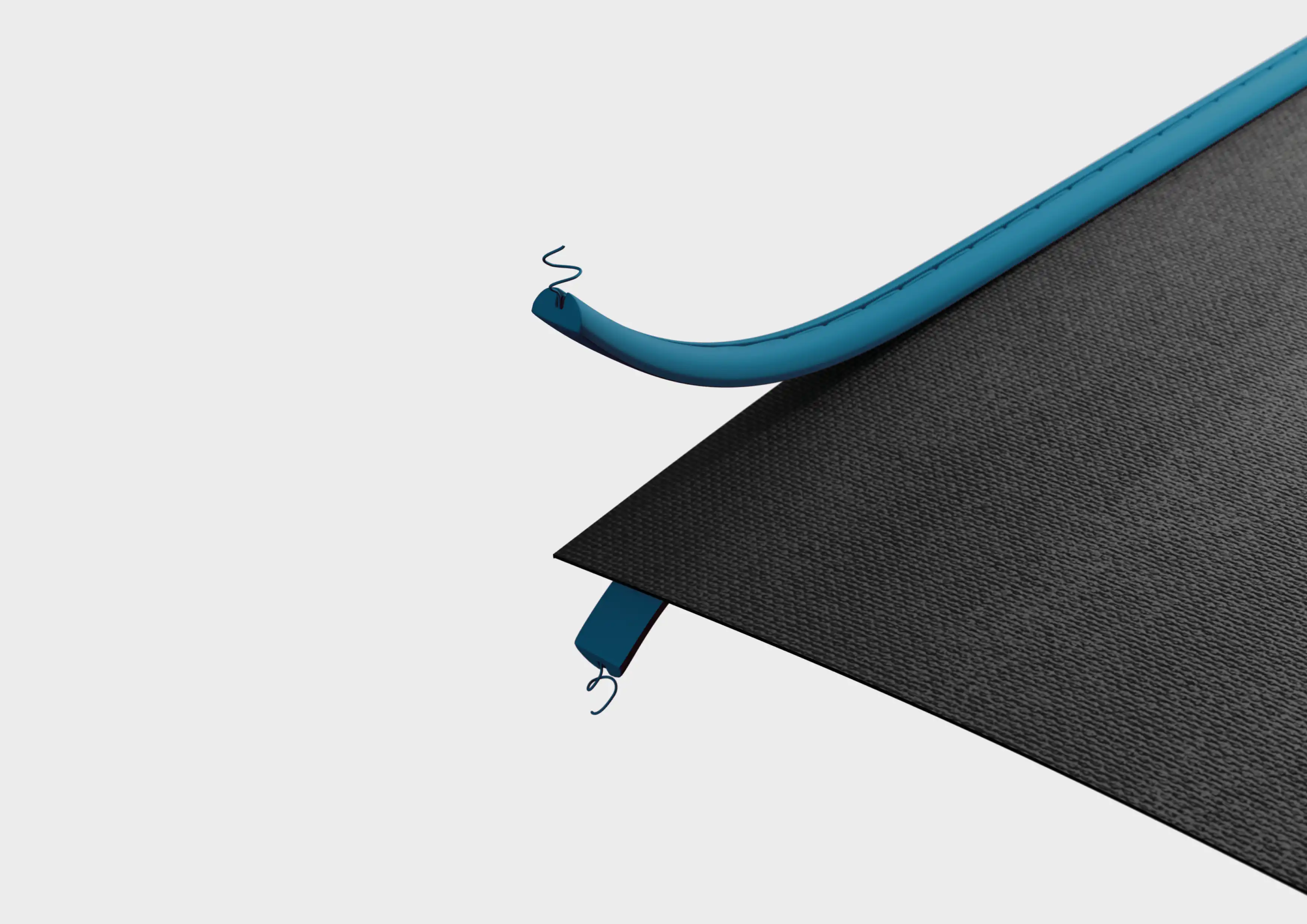

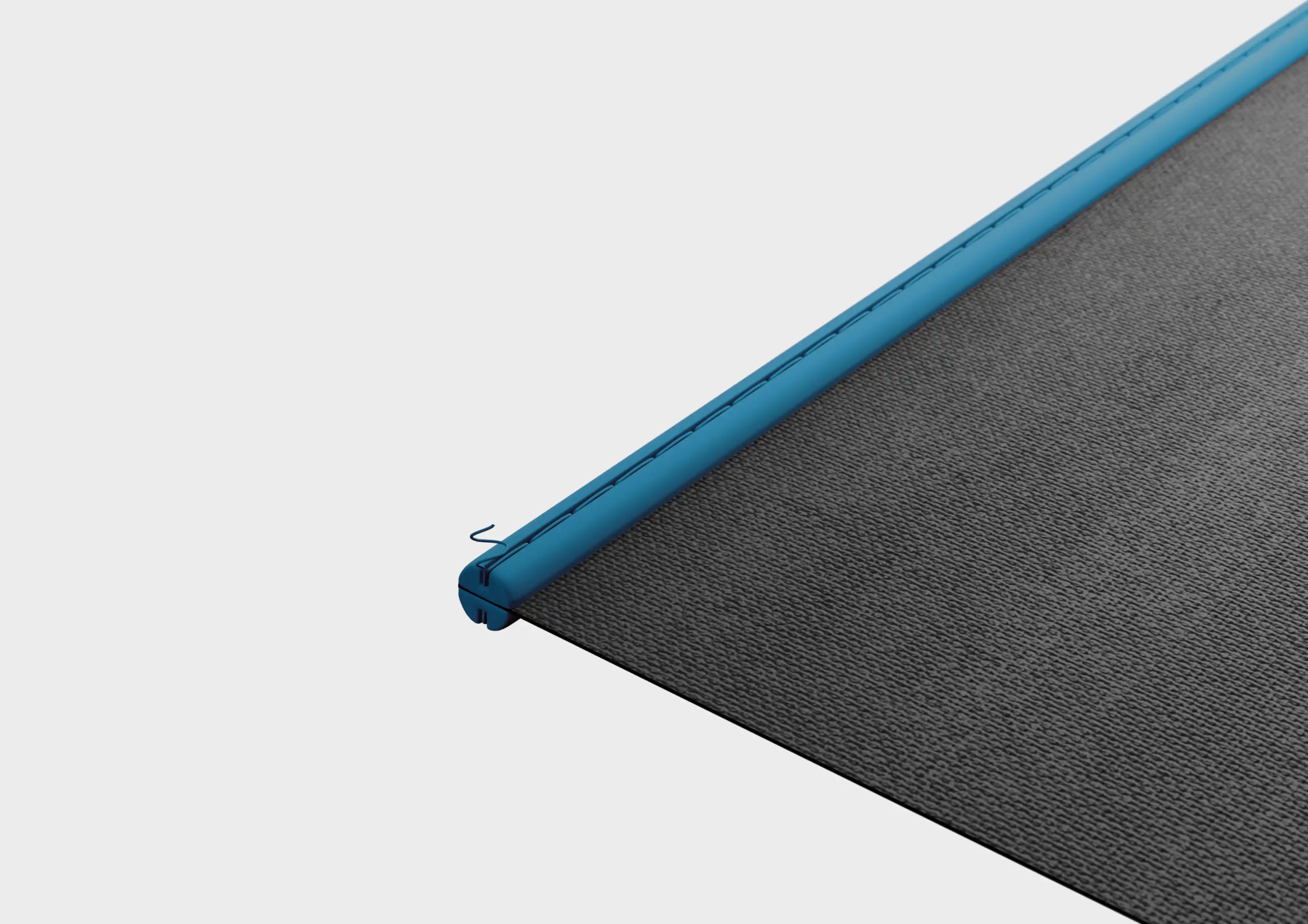

NonVi Twin S

The invisible and innovative keder hem seam!

The NonVi Twin consists of two half pipings with a groove. The fabric is guided between the keder halves, sewn and joined together with a force-fit.

The NonVi won the Gold Award in the "Textile sun shading" category at R+T 2021.

EQUIPMENT

The Kesa 4.0 can be configured with various optional features.

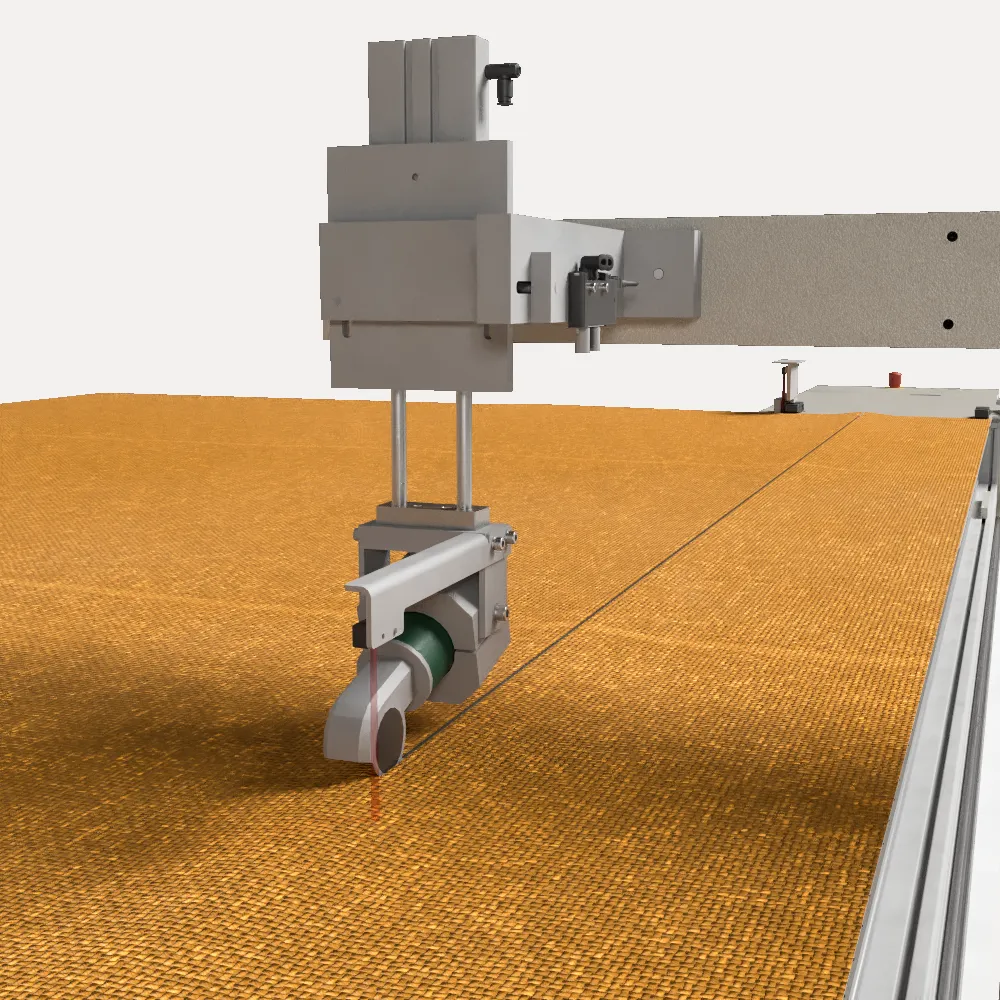

VALANCE CUTTER

VALANCE CUTTER

REWINDER

PVC SPLINE ROLL HOLDER

PVC SPLINE ROLL HOLDER

Helps the operator to select and unwind different types of piping.

REWINDER MOVEABLE

The electronic winding support helps to wind up the fabric and prepare the upper edge of the fabric for the next operation.

REWINDER FIX

The electronic winding support helps to wind up the fabric and prepare the upper edge of the fabric for the next operation.

VALANCE CUTTER

A volant cutter can be mounted on the platform of the mobile sewing head as a rotary knife or as an ultrasonic knife.

AUTOMATIC TRANSPORT

With the connection to an automatic transport system, the finished awning fabric is transported to the side.

ASSEMBLY TABLE

The assembly table can also be designed as an air cushion table.

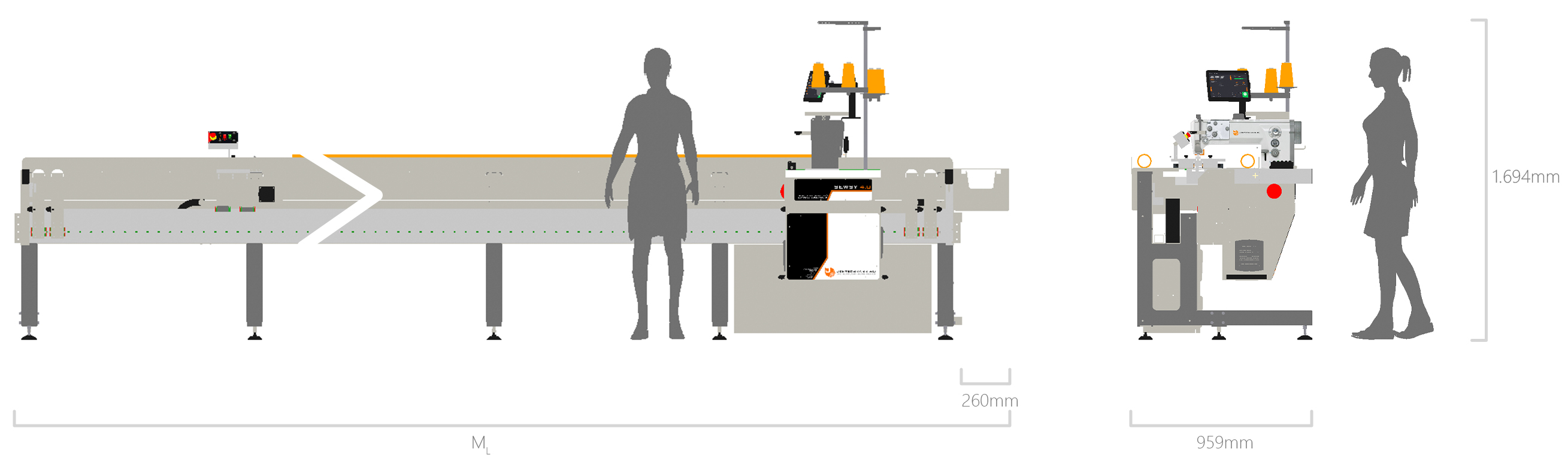

TECHNICAL DATA

The data may vary depending on the version.

-

Operating lengths

Operating length: Machine length (ML): 5.000mm 6.420mm 6.000mm 7.620mm 7.000mm 8.820mm 8.000mm 10.020mm 9.000mm 11.220mm 10.000mm 12.420mm -

Technical data

Sewing head: Dürkopp Adler 867

Stitch length: 5,5mm

Working speed: average app. 14m/min (depending on type of sewing thread and material)

Sewing speed: variable from 100 rpm to 3,000 rpm with constant stitch length -

Fabrics

Suitable for processing typical technical textiles such as: for exterior sun shading or digital printing industry

-

Dimension and weight

Height: 1.694mm (working height 900mm)

Length: variable (ML)

Depth: 959mm

Weight: 650kg to 1.060kg (depending on length and equipment)

-

Connection

Electrical power: 400V / 50Hz, 3 phases, 16A

Pneumatics: Ø 8mm, stable 8bar, dry, oil-free (class 0), 50l/min

Network: Ethernet (100/1000 Mbit)