BELTLINE SEW

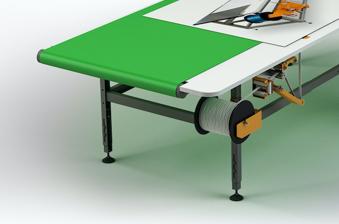

The Beltline is a sewing machine with a synchronized conveyer for sewing hems, piping and Velcro tapes on banners and other printed fabrics.

TECHNOLOGY

FLATPIPING

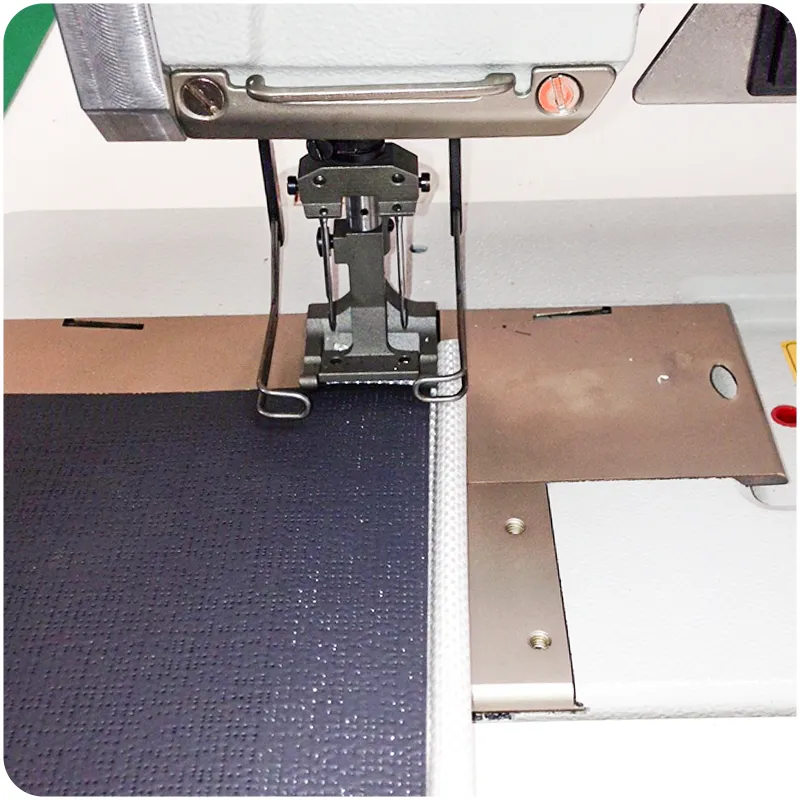

The flat piping roll is inserted into the corresponding holder on the left-hand side of the machine, below the table. The optional feed unit with dancer control ensures that the piping is fed to the sewing machine without distortion.

The printed material is positioned with the image side over the flat piping and sewn directly onto the piping using a precise guide.

The optional keder separation unit enables the keder to be separated quickly before the end of the seam.

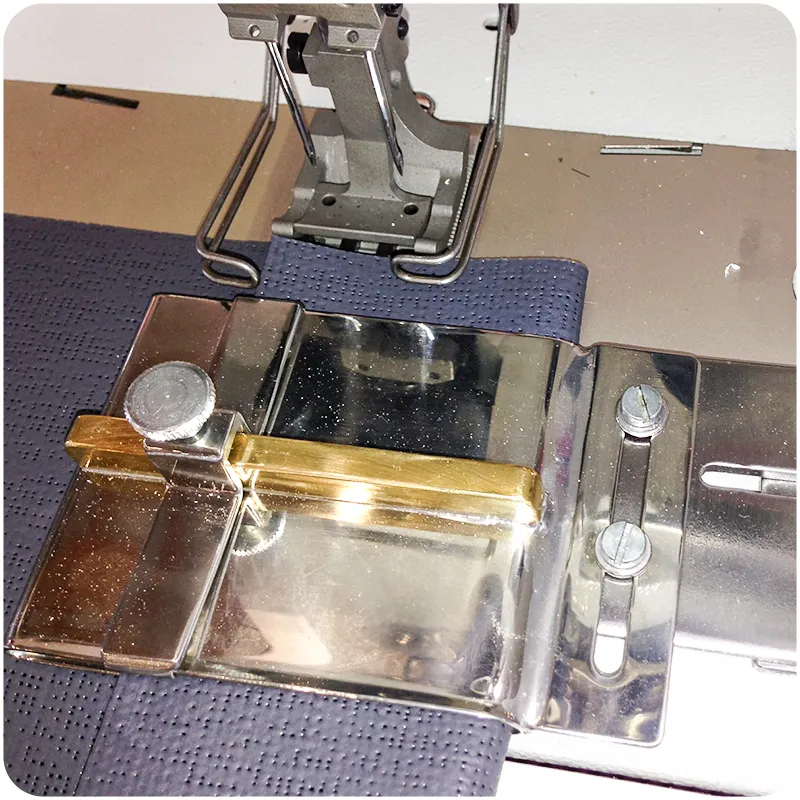

VELCRO

Velcro, fleece, or similar tapes can undergo processing by incorporating suitable guides. Adjustable devices ensure the processing of different tape widths.

FLAG PIPING

The processing of flag / tent piping is also possible by inserting a special guide device.

HEMSTITCH

After the material has been inserted into the in and out swivelling hemmer, the sewing process starts using the foot pedal, whereby the sewing speed within the seam can be regulated using the foot pedal.

Sewing can be so easy

Sewing of a flat piping with a synchronized conveyor belt is an effortless process that can be completed in no time at all.

PROCESSING

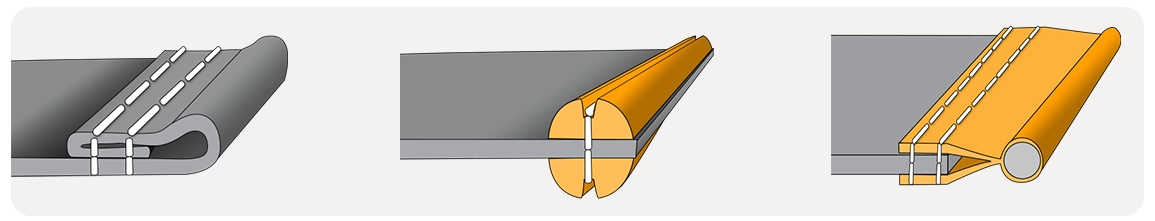

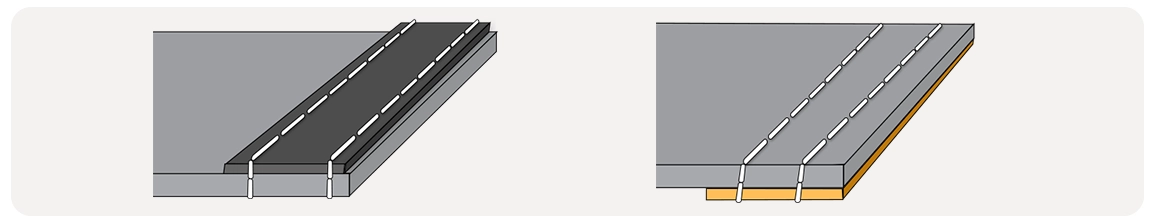

Typical edge finishes for the production of banners and flags:

Hemstitch / NonVi Twin S / Flag piping with 2 flags

Other typical edge finishes for the production of banners and flags:

Velcro tape (hook and loop tape) / flat piping

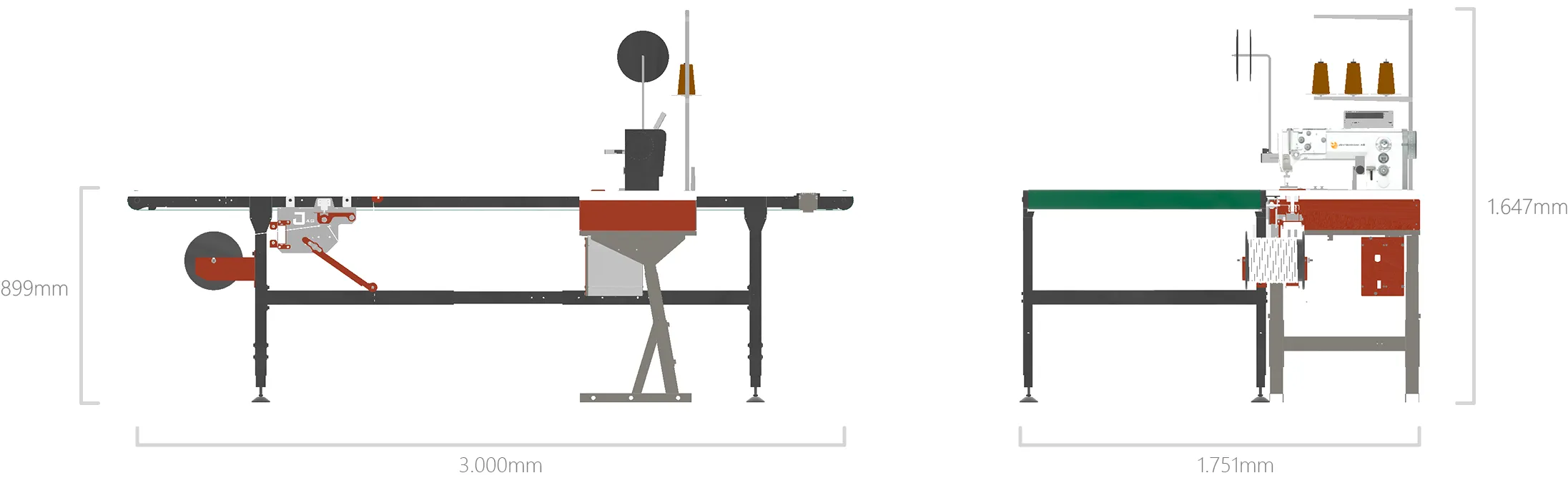

Technical data

The data may vary depending on the version.

-

Operating lengths

Max. oparationg length: Machine length (ML): Endless 3000mm -

Technical Data

Sewing head: Dürkopp Adler 867

Standard needle distance: 16mm

Stitch length: 6mm

Working speed: average app. 14m/min (depending on type of sewing thread and material)

Sewing speed: infinitely variable from 100 rpm to 3,000 rpm with constant stitch length -

Types of fabric

Suitable for processing technical textiles such as e.g: PVC-coated fabrics, polyester fabrics, acrylic fabrics, etc.

-

Dimension and weight

Table height: 870mm - 925mm (Complete height 1647mm)

Length: 3000mm

Depth: 1.751mm

Weight: ca. 270 kg (depending on the equipment)

-

Connection

Electrical power: 230V / 50Hz, 1 Phase, 6A

Pneumatics: Ø 8mm, stabel 6bar, dry, oil-free